Understanding the rPET compounding challenges

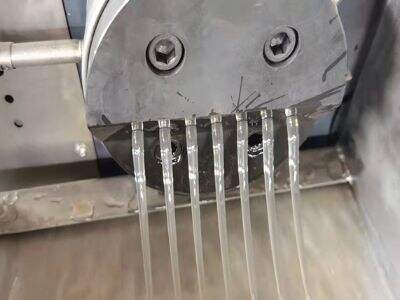

Processing compounding with rPET can be very challenging. rPET is short for recycled polyethylene terephthalate (the plastic made from recycled used plastic bottles). Recycling PET means doing a compounding: mixing the rPET with other materials to obtain products

Decontamination of the recycled material for rPET compounding is one of the more difficult issues. Possible contaminants can decrease the final quality to provide a less durable product. Inject it into a demand for more rPET and higher quality rPET means that compounding houses like MOOGE need to put considerable resources behind their PET Recycling Line to enable the use of the best possible processing fraction

Sustainability Compatible Materials Innovation in compounding

Thankfully, over the last several years, many of these ecologically efficient material advancements have been made for compounding. Some companies, like MOOGE, have begun to dabble in bio-based or recycled materials that may be more environmentally friendly. These materials will not only healthier for the planet but also enhance the quality of the final product

Among these we can mention the use of bio-based additives in the compounding step. Since manufactured from plant and algae-based materials, these ingredients are a much less environmentally detrimental process than standard chemical additives. This plastic recycling machine allows the companies to utilize less oil-based materials and lower their carbon footprint

rPET Compounding Optimization Strategies

In the compounding of rPET, sustainability challenges can be addressed by driving efficiency into their operations. Companies like MOOGE have taken an approach that has proven successful: investing in cutting-edge equipment capable of processing rPET more rapidly and effectively. This saves both energy and resources in the production process, as well as increasing the throughput of the compounding system

The environmental challenges in rPET compounding are

It is the single major concern in the compounding industry that can be easily met by adopting the use of limestone. MOOGE is working tirelessly to address these concerns with the help of Sustainable Practices and Processes. One way is turning to renewables to power their compounding equipment, for example via solar or wind energy production

Case studies of companies surmounting sustainability challenges in compounding operations

While rPET compounding can be challenging, sustainability obstacles in the process have been cleared by many businesses. The success of companies like MOOGE indicates that given the right efforts and creativity, it is completely within our capability to create great products in an environmentally responsible way

MOOGE success story MOOGE also has a new compounding process that uses 100% recycled materials. MOOGE has been able to achieve the quality levels that their products require but with an advanced level of sustainability by only utilizing recycled materials. It also increases their social life and this is equally beneficial to other companies in the industry as well

In summary, the profession of overcoming sustainability obstacles in pet recycling machine poses a stiff challenge to the plastic and allied sciences — to make changes happen and trigger different experiences within our environment. MOOGE is at the forefront of many an effort to sustainable product using bio-based material, effective processes or green energy sources etc. Solving these challenges help make a brighter compounding future possible

AR

AR

BG

BG

HR

HR

CS

CS

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

BE

BE

MK

MK

HY

HY

AZ

AZ

KA

KA

HT

HT

BN

BN

HMN

HMN