Intelligent Online NIR and AI Combination Use in Accurate Classification of Plastic Flake

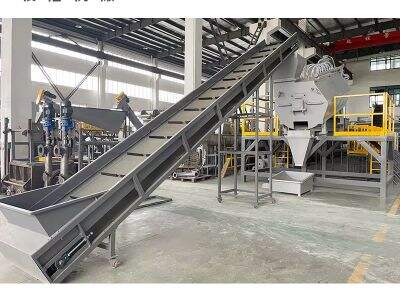

MOOGE is responsible for spearheading industrial manufacturing by an enterprise, commitment to quality and customer-centric philosophy. One of the aspects in which MOOGE is professional and has its advantages on advanced products is the combination of Smart NIR (Near Infrared) technology and AI (Artificial Intelligence) for accurate sorting/identification of plastic flakes. This state of the art integration of technologies results in precise and high-throughput sorting of PET flakes according to material type and quality

Intelligent NIR and AI Combination for accurate plastic flake sorting

The Smart NIR technology and the AI algorithms make it possible to classify plastic flakes with high accuracy. By interpreting the near infrared spectrum of each flake, the system is able to rapidly determine whether the flake is made of the type of plastic material it should be or if it has contaminants or impurities. This precision means only the best materials are chosen for further process ensuring higher quality overall product and less wasted material

Besides, AI in the classification itself poses real-time adjustments and optimizations in accordance with the system feedback. For instance, if there is reoccurring misclassification of a certain plastic flake type then the AI model can be fed this data to learn and adjust so that it can work more accurately going forward. It’s an adaptive quality that helps to keep the classification process effective and efficient despite new materials or contaminants entering the system

Intelligent NIR and AI in precision recycling of plastics

In precision plastic recycling, the combination of MOOGE‘s Smart NIR and AI has many advantages. By, for instance, properly categorizing plastic flakes by composition, the system can improve recycling methods by managing all materials in the most efficient manner. This not only improves the quality of recycled materials, but also increases the overall efficiency of recycling

Furthermore, thanks to AI combined with Smart NIR, MOOGE can analyze a great deal of data in no time and with precise location. This data may be employed to discover recycling trends and patterns, which will help drive further optimization and improving the system. For instance, the system might be able to recognize what types of containments commonly appear in recycled materials and direct corrective activity to minimize it from occurring in the future

Its advanced technology of Smart NIR and AI is reaching a new milestone to classify precision plastic flake for industrial manufacturing from MOOGE. With access to world-class technology, MOOGE is able to operate more accurately, efficiently and with a higher degree of quality in all the recycling services it offers and that benefits both the company and the environment

Optimising Plastic Flake Classification with Smart NIR and AI

MOOGE with Smart NIR (Near-Infrared), plus AI (Artificial Intelligence) to enhance plastic flake sorting technology. This technology allows it to recognize different types of plastic materials by their specific features using advanced sensors and algorithms so that the right one can be disposed in the appropriate recycling dump

The inclusion of Smart NIR means plastic flake can now be analysed on-site, rapidly and non-destructively locating the content and quality. AI algorithms then process this info, and the flakes can be classified with very high accuracy and speed. Automating that process, MOOGE's system removes human error and eliminates much of the time and cost involved in manual sorting

State of the art process for wholesale plastic recycling industry

In plastic recycling where processing efficiencies and profits are derived from reprocessed material quality, throughput with reliable operation is the key requirement for wholesale recycled plastics. With MOOGE’s Smart NIR combined with AI integration, we have a solution to answer this challenge for an easier and more efficient recycling of plastic

This problem can be solved with the use of this technological solution that will enable wholesale plastic recycling facilities to increase their processing and enhance capacity for producing high quality recycled materials whilst minimizing waste. With the infinite possibility of Smart NIR and AI, MOOGE is changing the traditional way to sort and classify plastic flakes, we are leading in this industry

Prospects of Smart NIR and AI in the plastic flake sorting

MOOGE Smart NIR and AI Integration provides a number of advantages for plastic flake sorting. One of the primary benefits is increased accuracy, because this technology can detect even slight variations in plastic material that a human pair of eyes may overlook. This produces a higher quality final product and more economical recycling

Furthermore the automation from Smart NIR and AI integration provides time and labour savings leading to efficient, cost effective recycling plant operation. By refining sorting, MOOGE’s technology also contributes to cutting back on contamination and ensuring that recycled products comply with industry guidelines

In summary, the introduction of Smart NIR and AI by MOOGE is a major technological breakthrough in plastic recycling, providing a smarter approach to classify your plastic flakes with sustainability be achieved. At the forefront of technology, MOOGE is committed to creating new standards and solutions for the wholesale recycling world

Table of Contents

- Intelligent Online NIR and AI Combination Use in Accurate Classification of Plastic Flake

- Intelligent NIR and AI Combination for accurate plastic flake sorting

- Intelligent NIR and AI in precision recycling of plastics

- Optimising Plastic Flake Classification with Smart NIR and AI

- State of the art process for wholesale plastic recycling industry

- Prospects of Smart NIR and AI in the plastic flake sorting

AR

AR

BG

BG

HR

HR

CS

CS

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

BE

BE

MK

MK

HY

HY

AZ

AZ

KA

KA

HT

HT

BN

BN

HMN

HMN