×

×

Komplette Anleitung zum Recyceln: Maschinen

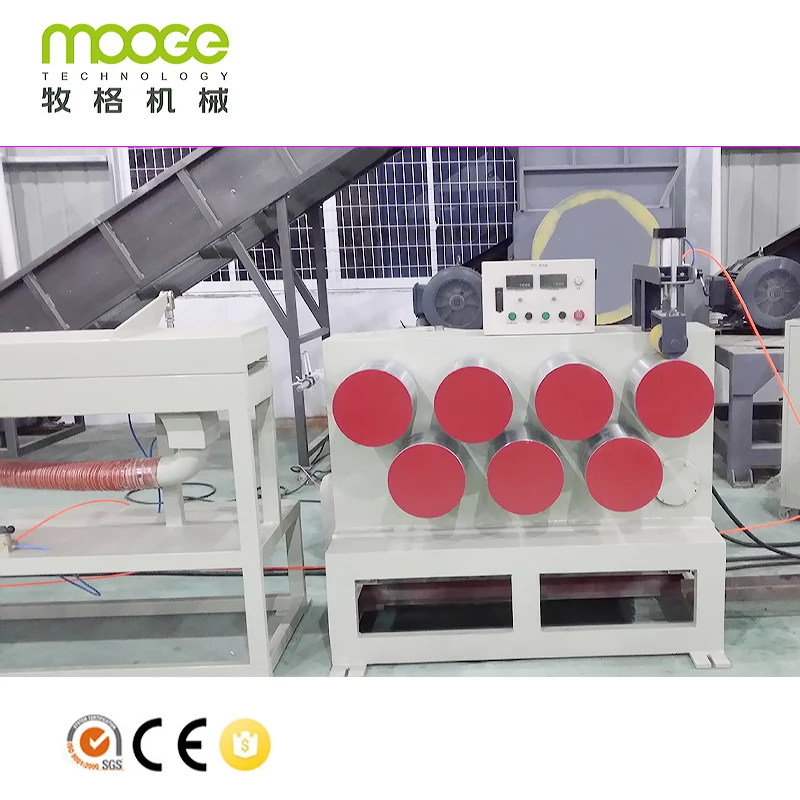

Plastik ist ein weiteres Material, das wir in jedem Lebensbereich verwenden. Allerdings hat diese Fülle an Plastik auch eine negative Auswirkung auf unsere Umwelt. Jedes Jahr enden etwa 8 Millionen Tonnen Plastikmüll im Meer, was das marine Leben beeinträchtigt und zur Verschmutzung beiträgt. Die Verbesserung des Recyclings sollte daher als oberste Priorität betrachtet werden, um dieser dringenden Herausforderung gerecht zu werden. Genau da kommt das pE-Film-Granulator von MOOGE ins Spiel.

Für alle, die im Recyclinggeschäft tätig sind, ist es zweifellos wahr, dass Sie bei Ihrer Arbeit nicht scheitern möchten. Hier sind einige Dinge zu beachten, wenn Sie über den Kauf einer PE-Film-Waschmaschine nachdenken.

Volumen: Bestimmen Sie die Größe Ihres Kunststoffabfalls und wählen Sie eine Maschine aus, die in der Lage ist, diese Menge zu recyceln.

Kosteneffektiv: Das Hauptziel einer Recyclinganlage ist es, Abfälle aus Recyclingströmen wirtschaftlich zu entfernen.

Haltbar: Wähle Ausrüstung, die 24 Stunden am Tag ohne häufige Pausen und Störungen funktioniert.

Kosten - Es ist alles offensichtlich, aber das, was du brauchst, geht über den Preis auf dem Schild hinaus!

Technik: Einige Verbesserungen könnten neue Funktionen in deinen Recyclingprozess durch moderne Maschinen einbringen. Also wähle eine Technologie, die deinen Bedürfnissen entspricht, und stelle sicher, dass die Maschine sie bietet.

Eine PE-Folien-Waschanlage bietet dir die Möglichkeit, die Effizienz und Wirksamkeit deines Recyclings zu verbessern, wie folgt:

Beste Recycling-Praktiken: Sie erhöhen die Recyclingstandards durch effizientes Reinigen von Kunststoffabfällen und deren Sortierung zur Entsorgung an Orten wie Deponien. wäscheleine für Plastikrecycling von MOOGE.

Günstig: Wenn du eine passende kaufst anstatt die Aufgabe manuell auszuführen, ist es kosteneffektiver, da manuelle Arbeit Ressourcen wie Wasser verbraucht.

Verbessert: Die Verwendung von up-to-date Technologie bedeutet, dass es Maschinen gibt, die eine Plattform schaffen können, um hohe Standards der Plastikrecycling zu erreichen, und sie mögen dabei helfen, Ihr Unternehmen wachsen zu lassen.

Rechtliche Einhaltung beim Einsatz von PE-Filmwaschmaschinen: Der Einsatz einer PE-Filmwaschmaschine hilft, einige Umweltgesetze einzuhalten, sodass dies als Vorteil bei der Reduktion rechtlicher Risiken genutzt werden kann.

Umweltverantwortung: Durch den Einsatz einer Waschanlage für PE-Film tragen Sie dazu bei, Plastikabfall zu minimieren und das Ökosystem zu schützen.

Finanzielle Vorteile - abgesehen von dem oben Erwähnten bietet der Kauf einer effizienten Recyclingmaschine Ihnen Kosteneinsparungen durch reduzierte Arbeitskräfte und Ressourcen.

Hochwertiges Produkt: Dieses System stellt sicher, dass die recycelten Plastike erworben werden, von hoher Qualität sind und zur Weiterentwicklung Ihres Unternehmens genutzt werden können.

Sicherstellt Compliance: Eine gute Recyclingmaschine ermöglicht es dir, alle Umweltstandards einzuhalten, ohne in rechtliche Verwicklungen zu geraten. Betriebs-effizienz: Recyclingmaschinen verringern die Recyclingzeit; das bedeutet, dass die Ressourcenausbeute strategischer wird und sich die Ausgabekualität verbessert.

Es ist ein Ticket, um gleichzeitig viele Folien zu recyceln; die PE-Folienwaschmaschine. Trotzdem können diese Maschinen Kosten sparen, indem sie andere Faktoren optimal handhaben, zur Verbesserung der regulatorischen Einhaltung beitragen und bessere Ergebnisse liefern, wenn ihre Präsenz für Sie von großer Bedeutung ist. Wenn Sie das Recycling erleichtern und Ihren Beitrag leisten möchten, die Umwelt zu schützen, dann ist keine bessere Zeit als jetzt, um in eine waschleitung aus Kunststoff von MOOGE.

PE-Folien-Waschmaschine, Auswahl von weit mehr als einem Dutzend Maschinen; Generatoren, Steuerungen und Schalter können je nach Bedarf beschafft werden.

Dies hängt tatsächlich von der Verkaufsmenge ab. Die Lieferzeit für unsere PE-Folien-Waschmaschine beträgt normalerweise 5–20 Arbeitstage.

Das Unternehmen bietet mit seiner PE-Folien-Waschmaschine eine Recycling-Lösung für den gesamten Extrusionsprozess von Kunststoff.

Wir bieten unseren Kunden einen 7*24-Stunden-Service. Sie können uns jederzeit leicht kontaktieren, unsere PE-Folienwaschmaschine wird langfristig verfügbar sein, um die beste Lösung anzubieten.