×

×

Model |

Pojemność |

Wyposażenie |

Użycie pary |

Zasilanie wodne |

Główna moc |

Wymagana powierzchnia |

MT-500 |

500 kg/godz |

190 KW |

Opcjonalnie |

4-5 m3/godz |

4-6 osób |

60*5*5 m |

MT-1000 |

1000 kg/godz |

260 kw |

Opcjonalnie |

6-8 m3/godz |

8-10 osób |

80*8*5 m |

MT-2000 |

2000 kg/godz |

400 kW |

Zalecane użycie |

10-15 m3/godz |

10-12 osób |

80*8*5 m |

MT-3000 |

3000 kg/godz |

600 KW |

80,000 Kcal |

20-30 m3/godz |

12-16 osób |

100*8*10 m |

MT-4000 |

4000 kg/godz |

800 KW |

100,000 Kcal |

30-40 m3/hr |

15-20 osób |

135*10*10 m |

MT-5000 |

5000 kg/hr |

1000 KW |

120,000 Kcal |

40-50 m3/hr |

15-20 osób |

135*10*10 m |

Zużycie energii jednostkowej |

||

Treść |

Średnie zużycie energii na tonę butelki |

|

ELEKTRYCZNOŚĆ |

70-90KW |

|

Woda |

1-1,5t/godz |

|

Sprężone powietrze |

0.5-1m3 |

|

Par (opcjonalnie) |

250-400KG |

|

Detergent (opcjonalnie) |

4-8KG |

|

Odwołanie do jakości strzępek z butelek |

||

Parametry techniczne |

Specyfikacje |

|

Rozmiar strzępek |

12-14mm |

|

Zawartość wilgoci |

<1%<> |

|

Zawartość PVC |

Mniej niż 100 ppm |

|

PH |

7.5 +/- 0.5 |

|

Wewnętrzna lepkość |

> 0.70 |

|

Nie-PET |

Mniej niż 100 ppm |

|

PET kolorowy |

Mniej niż 150 ppm |

|

Gęstość objętościowa |

250-400 kg/m³ |

|

Przydatne do użytku w |

Poliester / Pas PET / Włókno Poliestrowe / PSF / Arkusz PET |

|

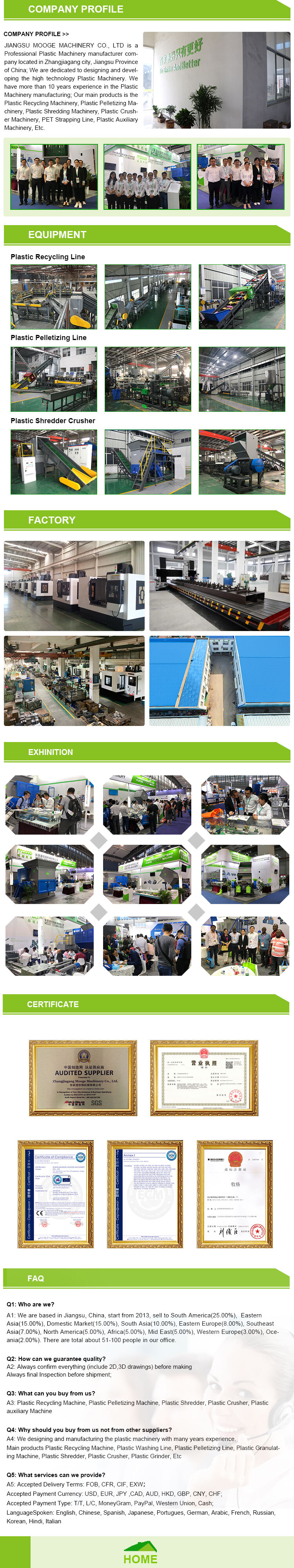

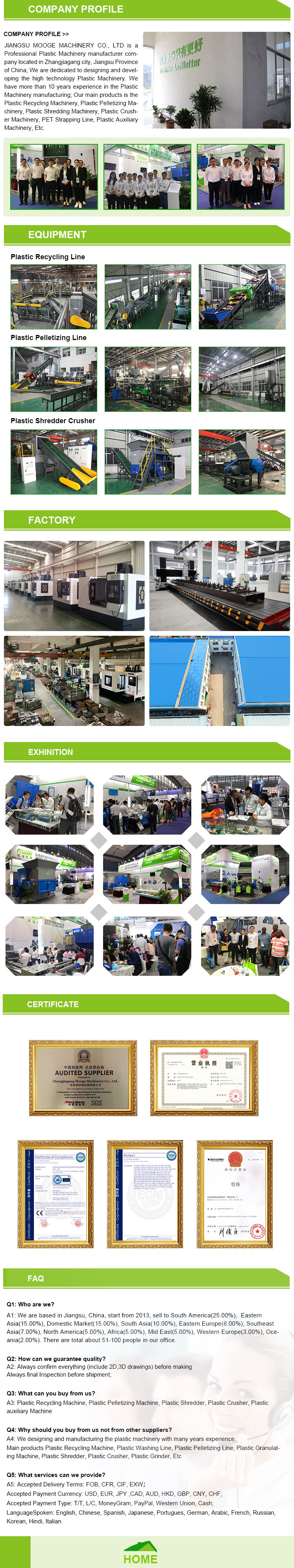

MOOGE

Szukasz ekologicznego rozwiązania do recyklingu butelek PET? Zerknij na linię recyklingową do mielenia i mycia parą butelek PET od MOOGE. Ten innowacyjny system został stworzony, aby znacząco pomóc osobom i przedsiębiorstwom w zmniejszeniu ich emisji węglowych i wypełnieniu swojej roli w ochronie środowiska.

Linia recyklingowa do mielenia i mycia parą butelek PET od MOOGE jest niesamowicie łatwa w użyciu. Po prostu wrzuć swoje butelki PET do urządzenia i pozwól mu wykonać całą ciężką pracę. Urządzenie zmiażdży butelki w małe kawałki, a następnie za pomocą gorącej wody usunie wszelkie nieczystości. Ten proces gwarantuje, że materiał recyklingowy jest najwyższej jakości, co czyni go idealnym do ponownego użycia.

Jedną z największych zalet tego produktu jest jego niesamowita wydajność. Linia recyklingowa do mielenia i mycia gorącym plastiku MOOGE PET Bottle może przetwarzać nawet 2000 kilogramów pojemników na godzinę, co czyni ją idealną dla firm wszelkich rozmiarów. Oferta nawet niskiego zużycia energii, co oznacza, że nie będziecie musieli martwić się o wzrost rachunków energetycznych.

Kolejną wielką zaletą produktu jest jego trwałość. Linia recyklingowa MOOGE PET Bottle Plastic Crushing and Hot Washing Recycling została skonstruowana tak, aby trwać długo, z mocną ramą i najwyższej jakości elementami, które będą radziły sobie z najtrudniejszymi zadaniami w zakresie recyklingu. Ponadto jej interfejs jest przyjazny użytkownikowi, co ułatwia obsługę i konserwację.

Jednym z najlepszych powodów do wykorzystania linii recyklingowej MOOGE PET Bottle Plastic Crushing and Hot Washing jest jej uniwersalność. Może być używana do recyklingu różnych produktów PET, w tym butelek, pojemników i materiałów opakowaniowych. To czyni ją idealnym rozwiązaniem dla firm z różnych branż, od żywności i napojów po kosmetyki i pielęgnację osobistą.

Oczywiście, jednym z najważniejszych zalet wyboru linii recyklingowej MOOGE PET Bottle Plastic Crushing and Hot Washing jest jej pozytywny wpływ na środowisko. Recyklingując produkty PET, możesz zmniejszyć ilość odpadów trafiających na wysypy i do oceanów. Pomaga to chronić dzikie zwierzęta, oszczędzać zasoby oraz promować bardziej zrównoważoną przyszłość.