×

×

Model maszyny |

RSS |

Marka |

MOOGE |

Materiał stosowany |

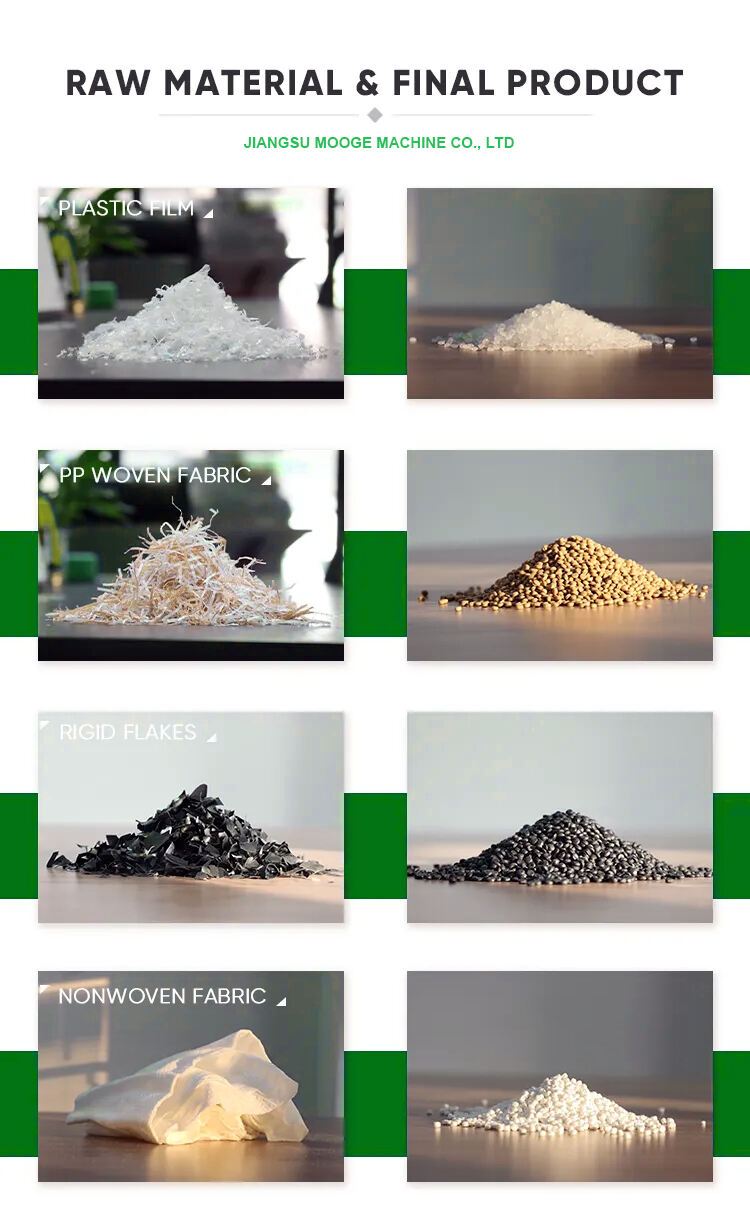

LDPE, LLDPE, HDPE, PP, BOPP, CPP, EPS, PS, PPS, ABS, PA, PLA |

Pojemność |

200-1200KG/H |

Średnica śruby |

80-180MM |

Projektowania śrub |

Pojedyncza śruba |

Stosunek l/d |

33-44/1 |

Obroty śruby |

90-180 |

Materiał śrub |

38CrMoAl |

Marka/typ reduktora |

Marka Guomao / Wysoki moment obrotowy pionowy |

Marka silnika |

SIEMENS lub chińska marka |

Strefa odgazowywania |

2 |

Typ pelletizera |

Wodny ringowy pelletizer |

Moc całkowita |

150-650KW |

Czas dostawy |

60 dni |

Gwarancja |

12 Miesięcy |

Certyfikat |

CE |

Parametr technologii |

Parametr technologii |

|||||||||||

Typ |

SJ-100 |

Sj-120 |

Sj-150 |

SJ-180 |

SJ-200 |

|||||||

Pojemność (kg/h) |

200-300 |

300-400 |

400-500 |

600-800 |

800-1000 |

|||||||

Zużycie energii (kWh/kg) |

0.2-0.3 |

0.2-0.3 |

0.2-0.3 |

0.2-0.3 |

0.2-0.3 |

|||||||

Ekstruder

|

Średnica śrubowa (mm) |

φ100 |

φ120 |

φ150 |

φ180 |

φ200 |

||||||

L/D |

33-44/1 |

33-44/1 |

33-44/1 |

33-44/1 |

33-44/1 |

|||||||

Moc silnika (kW) |

75 |

90 |

110 |

160 |

200 |

|||||||

Filtr

(opcje)

|

Płytowy typ dwupozycyjny |

● |

● |

● |

● |

● |

||||||

Typ tłoka dwupozycyjny |

○ |

○ |

○ |

○ |

○ |

|||||||

Typ odwrotnego spłukiwania tłoka |

○ |

○ |

○ |

○ |

○ |

|||||||

Typ automatycznego samoczyszczania |

○ |

○ |

○ |

○ |

○ |

|||||||

2nd Wytłaczarka

(nieobowiązkowe)

|

Średnica śrubowa (mm) |

φ100 |

φ120 |

φ150 |

φ180 |

φ200 |

||||||

L/D |

8-12/1 |

8-12/1 |

8-12/1 |

8-12/1 |

8-12/1 |

|||||||

Moc silnika (kW) |

30 |

45 |

55 |

75 |

90 |

|||||||

Strumień dolny (opcje)

|

Wodny ringowy pelletizer |

● |

● |

● |

● |

● |

||||||

Granulator nitkowy |

○ |

○ |

○ |

○ |

○ |

|||||||

Automatyczny wycinacz kulek |

○ |

○ |

○ |

○ |

○ |

|||||||

Podwodny pelletizer |

○ |

○ |

○ |

○ |

○ |

|||||||

Obsługa Przed Sprzedażą

1. Obsługa 24 godziny w ciągu dnia. Twoje zapytanie zostanie szybko odpowiedziane przez e-mail.

Można również rozwiązać wszystkie pytania za pomocą dowolnego narzędzia do rozmów online (WeChat, WhatsApp, Skype, Viber, QQ i Trade Manager).

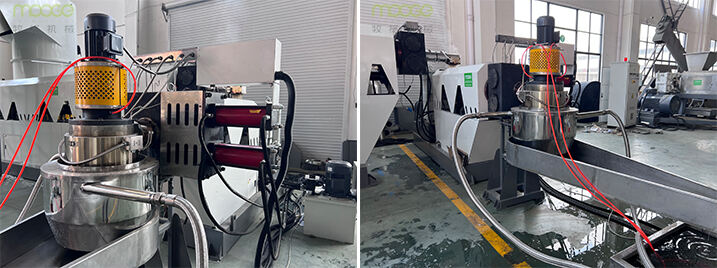

2. Profesjonalne i cierpliwe wprowadzenie, szczegółowe zdjęcia i film pracy, aby pokazać maszynę

Usługa w trakcie sprzedaży

1. Przetestuj każdą maszynę i poważnie ją sprawdź.

2. Wyślij zdjęcie maszyny, którą zamówiłeś, a następnie spakuj ją w standardowej drewnianej skrzynce eksportowej po twoim potwierdzeniu, że maszyna jest w porządku. 3. Dostawa: Jeśli przewozi się statkiem, po dostarczeniu do portu morskiego, poinformujemy Cię o czasie wysyłki i przybycia. W końcu wyślemy wszystkie originale dokumentów za darmo kurierem. Jeśli dostawa jest kurierska do Twojego miejsca (DHL, TNT, FedEx itp.) lub samolotem do Twojego lotniska, lub logistyka do magazynu, który żądasz. Poinformujemy Cię o numerze śledzenia po wysłaniu.

Serwis Po Sprzedaży

1. darmowe ubezpieczenie towarów

2. 24-godzinna obsługa online, aby rozwiązać każde pytanie. Udostępniamy Ci podręcznik w języku angielskim oraz wsparcie techniczne, filmy instruktażowe dotyczące konserwacji i instalacji, aby pomóc Ci rozwiązać problem, lub wyślemy pracownika do Twojej fabryki.

MOOGE

Maszyna do recyklingu i spakowywania odpadów z tworzyw plastikowych PP, PE, LDPE jest wysokiej jakości i niezawodną, została zaprojektowana do przekształcania miękkich filmów plastikowych PP i PE w granulat, który może być wykorzystywany w różnych zastosowaniach komercyjnych. Ta maszyna jest doskonała do recyklingu odpadów plastikowych i zmniejszania szkód dla środowiska spowodowanych przez odpady plastikowe.

Wykonana z materiałów najwyższej jakości, a także zaprojektowana do obsługi miękkich odpadów plastikowych PP i PE w prosty sposób. Urządzenie wyposażone jest w bardziej impresjonujące technologie, które gwarantują efektywny i ciągły proces recyklingu syntetycznego. Produkt jest łatwy w obsłudze, wymaga minimalnego utrzymania, co czyni go kosztowym rozwiązaniem do recyklingu odpadów plastikowych.

Wyposażony do radzenia sobie z szerokim zakresem plastików PP i PE, w tym miękkimi filmami, które są zabrudzone impuritymi takimi jak papier oraz inne odpady. Urządzenie zostało zaprojektowane do usuwania tych nieczystości i produkcji kulek najwyższej jakości, które mogą być wykorzystane w wielu zastosowaniach komercyjnych.

Krótka i oszczędna pod względem miejsca maszyna może być łatwo włączona do istniejącej linii produkcyjnej. Ta maszyna została stworzona do pracy na wysokich prędkościach, z możliwością przetwarzania do 800 kg/h, czyniąc ją wyjątkowo efektywnym rozwiązaniem recyklingu odpadów.

Składa się z przyjaznego użytkownikowi interfejsu, który umożliwia operatorom kontrolowanie i monitorowanie całego procesu recyklingu. Jednostka jest wyposażona w funkcje bezpieczeństwa, które gwarantują bezpieczne działanie, stanowiąc solidne rozwiązanie zarówno dla małych, jak i dużych operacji recyklingowych plastiku.

Maszyna do recyklingu i spakowywania filmów z odpadowego plastiku PP, PE, LDPE marki MOOGE jest bardzo wydajna, tania i godna zaufania w procesie recyklingu. Ten sprzęt będzie idealny dla firm chcących zmniejszyć swój wpływ na środowisko naturalne oraz wywrze pozytywny wpływ na środowisko. Produkt jest niezastąpiony dla każdej organizacji, która próbuje recyklingować odpady sztuczne dzięki swoim zaawansowanym technologiom, przyjaznemu interfejsowi użytkownika i funkcjom bezpieczeństwa.