×

×

Pelletizing Machines: A Sustainable Solution to Plastics Recycling

Plastic is a significant threat to our environment. Yet, it is important to note that plastic can be recycled and turned into new useful stuff. The last development in recycling was palletizing machines from plastic. It is the same as the plastic pelletizer machine of MOOGE. We will go over the benefits and why we are using pelletizing machines in plastic waste recycling.

Pelletizing machines for plastic waste recycling offer an array of benefits. Just like the pelletizer machine plastic of MOOGE, it can produce plastic waste into pellets. These are easy to handle and transport as well store but also reusable. This will also reduce the amount of plastic waste that would have gone to landfills or oceans. It means that raw materials are used more efficiently and less energy is consumed. Pelletizing machines are designed as an eco-friendly solution to deal with plastic waste.

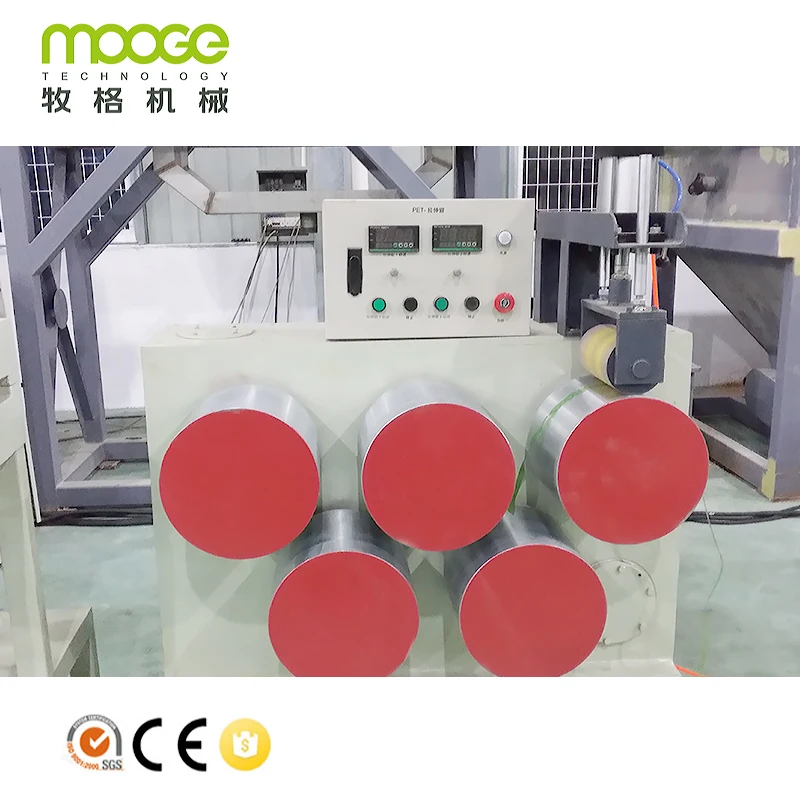

The pelletizing machines are considered to be a modern specialized advancement in plastic recycling. This plastic pelletizing machine of MOOGE uses advanced technology to convert plastic waste into pellets. They are made to be friendly for the user. It will also include easy maintenance and the ability of couture to serve diverge needs.

The safety of pelletizing machines is also a crucial issue. Safety measures are built directly into each machine. It helps take the danger and risk out of operating these machines. Every pelletizer machine has safety devices such as switches, emergency stop buttons, and interlocks. Safety protocols must be followed to avoid accidents in a pelletizing machine.

Pelletizing machines are used to change the littered plastic dump into small pellets. It is utilized in the making of many other products. Plastic pellets are used for a range of diverse applications. It is lightweight, uniform in quality and tailored to one needs. Those tiny particles of plastic waste are a sustainable way out.

Pelletizing machine for plastic recycling More when compared with a dozen motor providers from which to choose, generators, controllers, switches could feel chosen living in connection with demand.

Usually, our Pelletizing machine for plastic recycling time is between 5-20 trading days, is dependent on the total quantity of orders.

The team Pelletizing machine for plastic recycling and supply a solution that was overall vinyl extrusion and recycling. We have been aimed at designing and developing the high-tech Plastic Machinery.

You can contact us anytime,our Pelletizing machine for plastic recycling will respond immediately to provide you the ongoing better service. We offer 24 hours a, 7 days a service for ou clients day week.

The operation of the pelletizing machine is simple. First collect the plastic waste, and you can feed it with hopper or conveyor to a machine. They shred the plastic waste, and then they melt it down by applying heat and friction. The molten plastic is then extruded through a die into pellets. Cool and receive pellets after they clump up. It can be important to follow maker guidelines so that the pelletizing machine is working properly.

Pelletizing machines are complex equipment that requires to be maintained and serviced regularly. Stick to the maker's advice and also pay regular visits. Routine maintenance is imperative to ensure the machine functions as needed. It can seriously reduce downtime and working costs.

Pelletizing Machines are designed for the production of high-quality pellets used in various applications. The pellets are suitable for an automated production process. These machines are created to avoid impurity and preserve the standard of pellets they generate.