MOOGE

Urządzenia do Zmielania Plastików Zmielnica Dla Materiałów Twardych Pracuje Ciągle, ostateczne rozwiązanie potrzeb zarządzania odpadami plastikowymi. Ten produkt został zaprojektowany do mielenia i tnienia wszelkich materiałów plastikowych twardych, czyniąc to łatwiejszym do usunięcia i recyklingu.

Pracuje nieustannie, dzięki swojemu potężnemu silnikowi, który zapewnia stałe i wydajne spychanie. Może przetwarzać różne rodzaje twardego materiału plastikowego, w tym butelki PET, rury PVC i pojemniki HDPE oraz inne.

Ten miotacz plastikowy został stworzony, aby trwać, z trwałą i solidną konstrukcją, która może wytrzymać długie godziny pracy. Dodatkowo wyposażony jest w ostrze high-performance, które jest wystarczająco mocne, aby spychać i tnąć nawet najtrudniejsze materiały plastikowe.

Jest projektowany tak, aby być łatwy w użyciu, z prostą tablicą kontrolną, która umożliwia dostosowanie prędkości i wydajności spycharki, a także jej trwałości i efektywności. Oznacza to, że możesz dostosować proces spychania do swoich preferencji, co gwarantuje brak kłopotów.

Jednym z najlepszych aspektów tego mielarka plastikowego jest to, że jest przyjazny środowisku. Miażdżąc i tnąc odpady plastikowe zmniejszasz ilość plastiku, która kończy się na wysypiskach lub w oceanach, co jest bardzo korzystne zarówno dla środowiska, jak i dla twojego biznesu.

Używanie tego urządzenia może nie tylko oszczędzić Ci pieniądze na kosztach zarządzania odpadami, ale również pomoże Ci w przestrzeganiu przepisów ekologicznych i zmniejszeniu Twojego wykorzystania węgla.

Więc, nie pozwalaj, aby Twoje odpady plastikowe się nagromadzały czy stały się obciążeniem. Zainwestuj w mielarkę plastikową MOOGE do materiałów twardych, która działa ciągle i weź teraz kontrolę nad potrzebami zarządzania Twoimi odpadami plastikowymi. To niezawodne, efektywne, trwałe i przyjazne środowisku rozwiązanie, które z pewnością ułatwi Ci życie.

Właściciel Série Maszyna do mielenia plastiku - Dla butelek PET/PP/PE/HDPE, wiader, pustych pojemników.

Służy do butelek PET, plastikowych butelek, wiader, pustych pojemników itp.

Dzięki specjalnemu projektowi konstrukcyjnemu, będzie miało większą pojemność przy mniejszym zużyciu energii.

Główne cechy:

1. Ramy wykonane są z grubego rurociągu kwadratowego.

2. Wał wykonany jest z nierdzewnej stali 45# z obróbką termiczną.

3. Komora wykonana jest z grubej stali o grubości 40 mm.

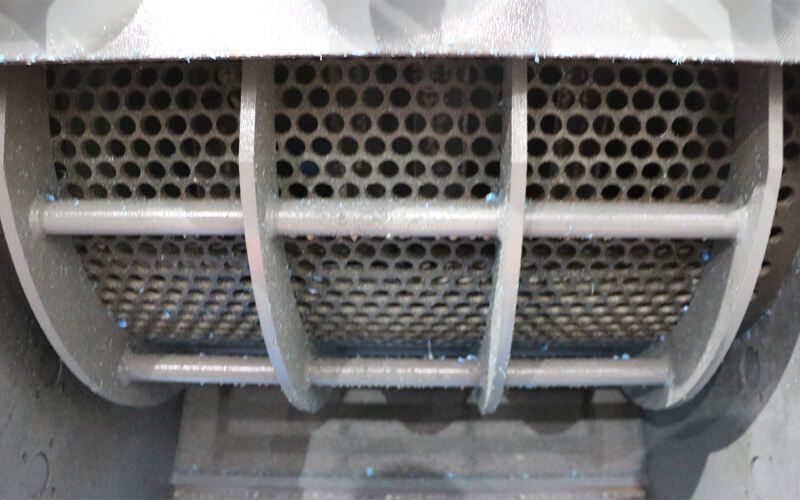

4. Siatka jest wykonana z stalowej blachy o grubości 10 mm zapewniającej trwałe użytkowanie.

5. Projekt umożliwiający łatwe demontaż, komora otwierana jest automatycznie za pomocą silnika, co ułatwia czyszczenie i konserwację oraz sprawia, że zmiana ostrzy jest wygodna.

6. Zastosowano zewnętrzne zamontowanie domku łożyskowego, dzięki czemu brud nie dostaje się do środka, co przedłuża czas użytkowania.

7. Górna część maszyny jest wyższa i przykryta pasem, przez co żadne strzępki nie wypadają na zewnątrz.

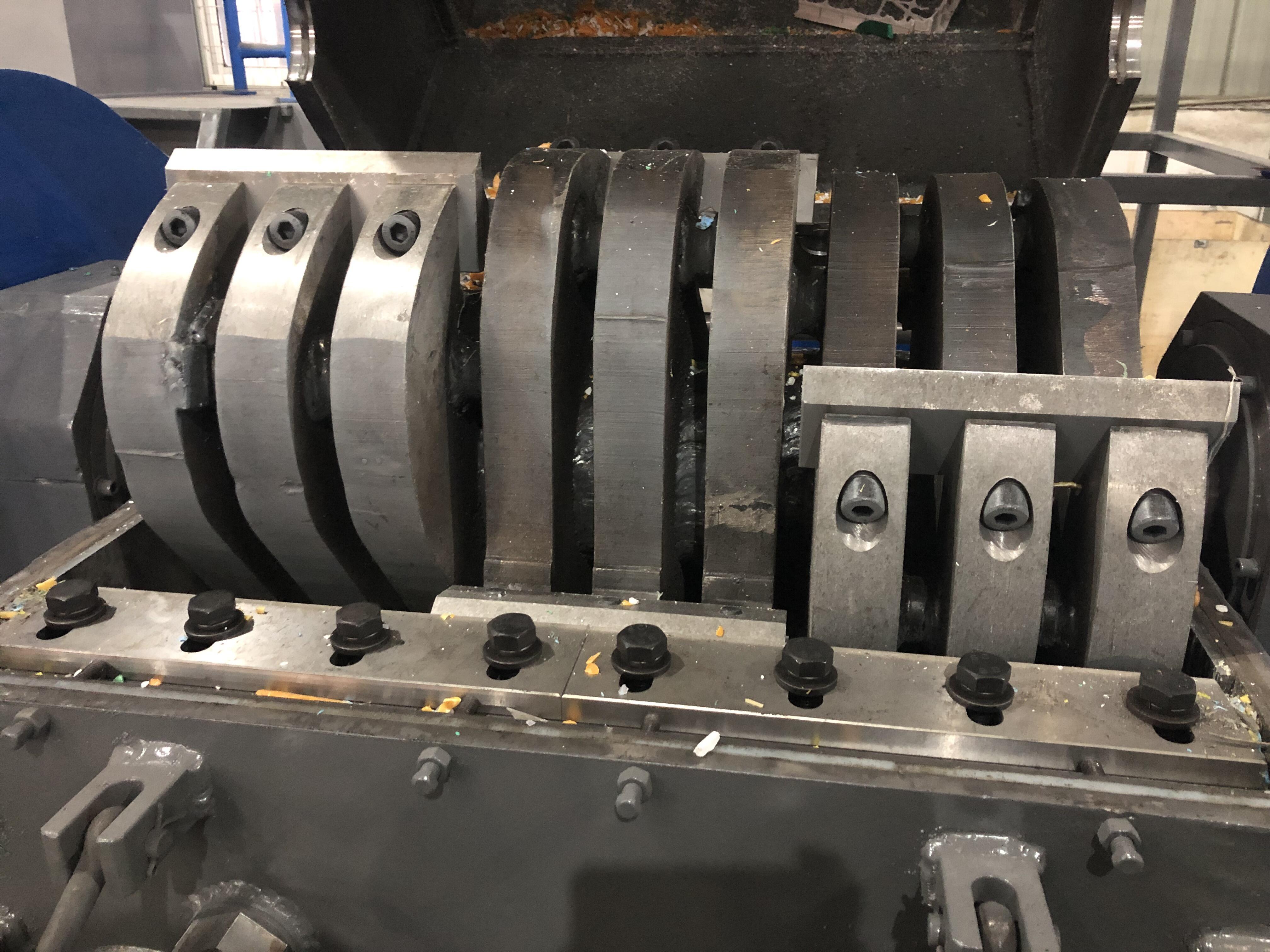

8. Noże są wykonane z odznaczającego się najwyższą jakością materiału SKD-II pochodzącego z Japonii.

9. Specjalnie zaprojektowana krzyżowa struktura cięcia zapewnia dużą przepustowość oraz niskie zużycie energii.

Model |

S-600 |

S-800 |

S-1000 |

S-1200 |

S-1500 |

Ostrze wirujące |

8 |

8 |

8 |

8 |

8 |

Stałe ostrze |

4 |

4 |

4 |

4 |

4 |

Ekran |

14/16 mm |

14/16 mm |

14/16 mm |

14/16 mm |

14/16 mm |

Moc |

30KW |

37/45KW |

45/55KW |

55/75KW |

75/90KW |

Pojemność |

300kg/h |

500kg/h |

800-1000kg/g |

1000-1500Kg/godz. |

1500-2000kg/g |

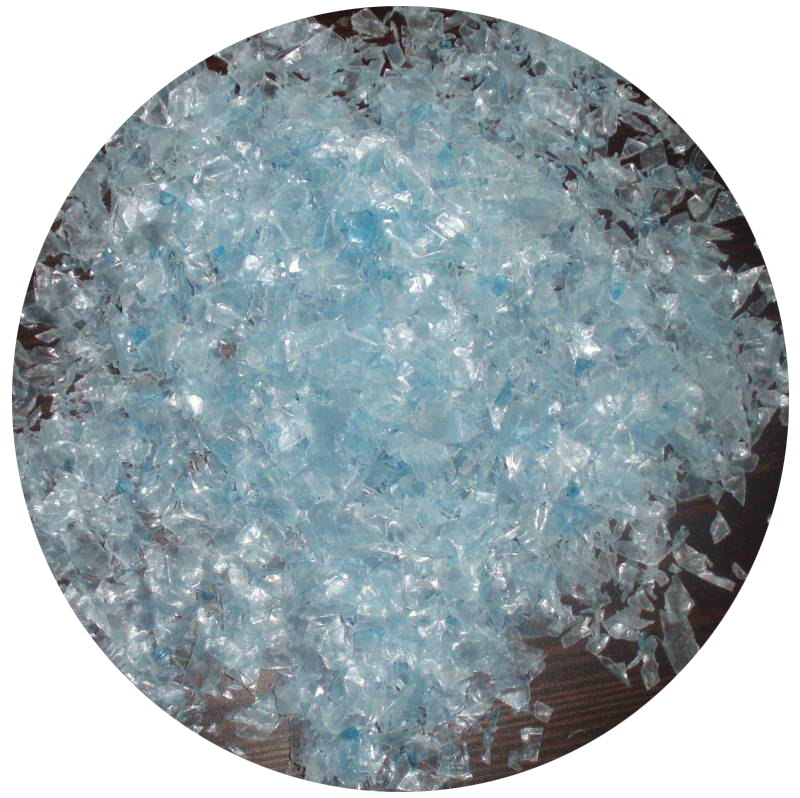

Materiał końcowy Zredukowany do płatków.

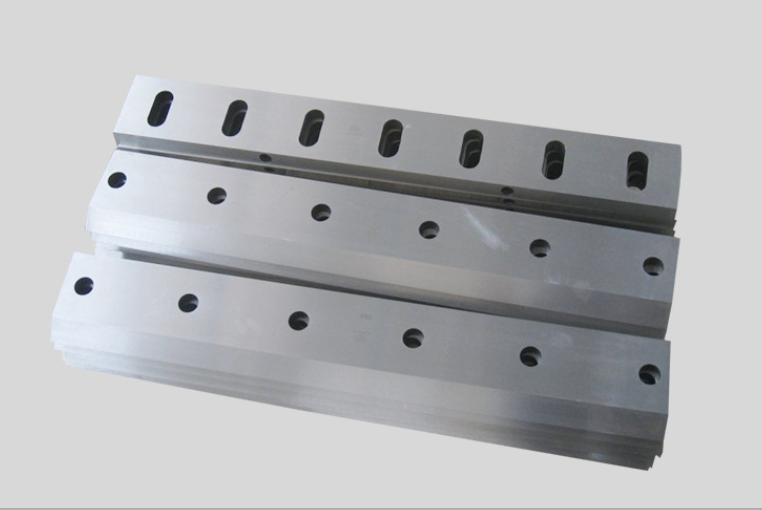

Statyczna klinga: Ostrza szerokie mogą być ostrygane 20-25 razy, co zaoszczędzi koszt ostrzy. Materiał: 9Crsi/SKD-11/D2.

Rotor: Z mocnym wirnikiem i wałem.

Wał wykonany z nierdzewnej stali 45# z przetwórstwem termicznym.

Siatkowanie: Średnica siatki: 14mm,

Grubość siatki: 10mm

Motor: Utrzymuje dobrą wydajność silnika i może być używany przez długi czas.

Używany w linii mycia recyklingu butelek PET

Używany w linii mycia recyklingu butelek HDPE

AR

AR

BG

BG

HR

HR

CS

CS

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

BE

BE

MK

MK

HY

HY

AZ

AZ

KA

KA

HT

HT

BN

BN

HMN

HMN