MOOGE

Maszyna do mielenia odzysku z preform PET PP plastikowych i zmielnik butelek odpadowych może być idealnym rozwiązaniem dla każdego, kto próbuje recyklować i minimalizować odpady. Ten produkt został skutecznie opracowany w celu szybkiego i efektywnego mielenia różnych materiałów sztucznych, co czyni go doskonałym dodatkiem do prawie każdego centrum recyklingowego lub miejsca pracy.

Wykonana z materiałów najwyższej jakości, MOOGE maszyna do mielenia odzysku z preform PET PP plastikowych i zmielnik butelek odpadowych została zaprojektowana na długoterminowo. Posiada ona solidną i trwałą konstrukcję, a także niezawodne elementy i mechanizmy, które gwarantują stały wydajność w czasie.

Jedną z najważniejszych cech tego produktu jest jego imponujące zdolności do mielenia. Maszyna do mielenia odzysku z preform PET PP plastikowych i zmielnik butelek odpadowych może zmielić do 600 kg materiału sztucznego w ciągu godziny, co czyni ją wydajnym i efektywnym urządzeniem do redukcji odpadów dzięki swojemu potężnemu silnikowi i ostrym ostrzem.

Ten przyrząd jest zazwyczaj bardzo uniwersalny oprócz swojego imponującego zdolności do mielenia. Mogłby być używany do mielenia wielu materiałów sztucznych, w tym pojemników dla zwierząt, preform PP i wielu innych rzeczy. To może umożliwić jego wybór jako doskonały dla dowolnego centrum lub miejsca pracy, które dotyczy licznych elementów odpadów syntetycznych.

Maszyna do mielenia odpadowych butelek PET PP Preform Recycle Grinder jest zwykle przystępna dla użytkownika. Oferta prostej i intuicyjnej kontroli umożliwia operatorom łatwo dostosowywać ustawienia i funkcje urządzenia, co sprawia, że jest bardzo łatwa w obsłudze i pozostaje efektywna.

Na koniec, ten przyrząd jest zazwyczaj bardzo prosty i trwały w obsłudze. Inkluduje solidny i godny zaufania projekt, który został zaprojektowany, aby wytrzymać wymagania ciężkiego użytkowania i regularne uszkodzenia. Ponadto, składający się z łatwych do uzyskania elementów, projekt przystępny dla użytkownika czyni go również bardzo łatwym w utrzymaniu i zachowaniu w najlepszym stanie.

Właściciel Série Maszyna do mielenia plastiku - Dla butelek PET/PP/PE/HDPE, wiader, pustych pojemników.

Stosowane do

Butele PET, butelki plastikowe, wiadra, puste pojemniki oraz inne materiały plastikowe. Dzięki specjalnemu projektowi konstrukcyjnemu ma większą pojemność przy niższym zużyciu energii.

Główne cechy:

1. Ramy wykonane są z grubego rurociągu kwadratowego.

2. Wał wykonany jest z nierdzewnej stali 45# z obróbką termiczną.

3. Komora wykonana jest z grubej stali o grubości 40 mm.

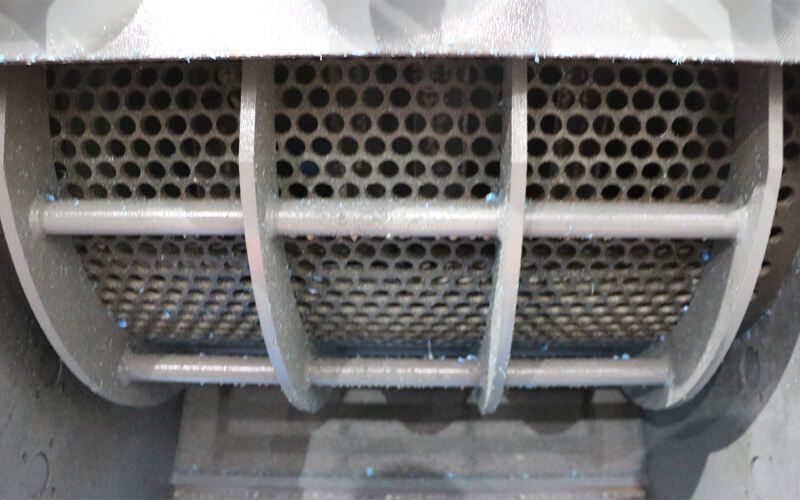

4. Siatka jest wykonana z stalowej blachy o grubości 10 mm zapewniającej trwałe użytkowanie.

5. Projekt umożliwiający łatwe demontaż, komora otwierana jest automatycznie za pomocą silnika, co ułatwia czyszczenie i konserwację oraz sprawia, że zmiana ostrzy jest wygodna.

6. Zastosowano zewnętrzne zamontowanie domku łożyskowego, dzięki czemu brud nie dostaje się do środka, co przedłuża czas użytkowania.

7. Górna część maszyny jest wyższa i przykryta pasem, przez co żadne strzępki nie wypadają na zewnątrz.

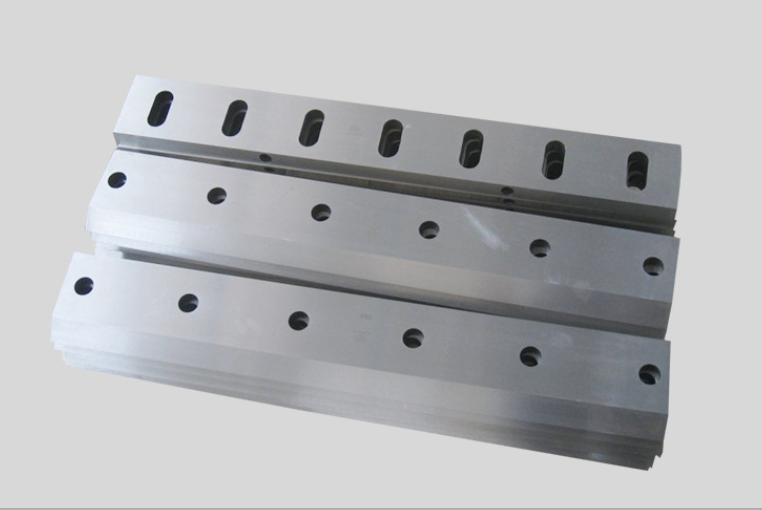

8. Noże są wykonane z odznaczającego się najwyższą jakością materiału SKD-II pochodzącego z Japonii.

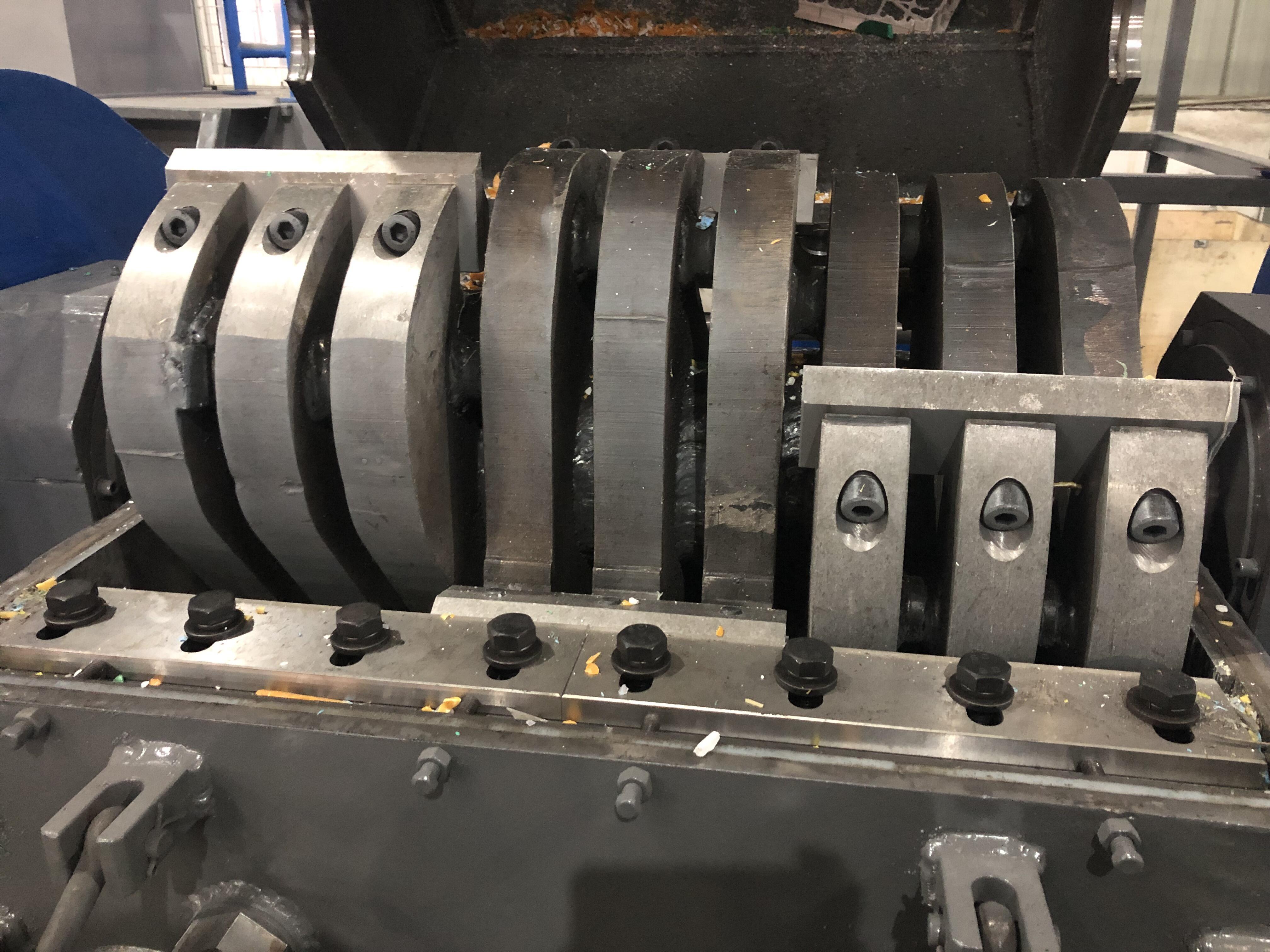

9. Specjalnie zaprojektowana krzyżowa struktura cięcia zapewnia dużą przepustowość oraz niskie zużycie energii.

Model |

S-600 |

S-800 |

S-1000 |

S-1200 |

S-1500 |

Ostrze wirujące |

8 |

8 |

8 |

8 |

8 |

Stałe ostrze |

4 |

4 |

4 |

4 |

4 |

Ekran |

14/16 mm |

14/16 mm |

14/16 mm |

14/16 mm |

14/16 mm |

Moc |

30KW |

37/45KW |

45/55KW |

55/75KW |

75/90KW |

Pojemność |

300kg/h |

500kg/h |

800-1000kg/g |

1000-1500Kg/godz. |

1500-2000kg/g |

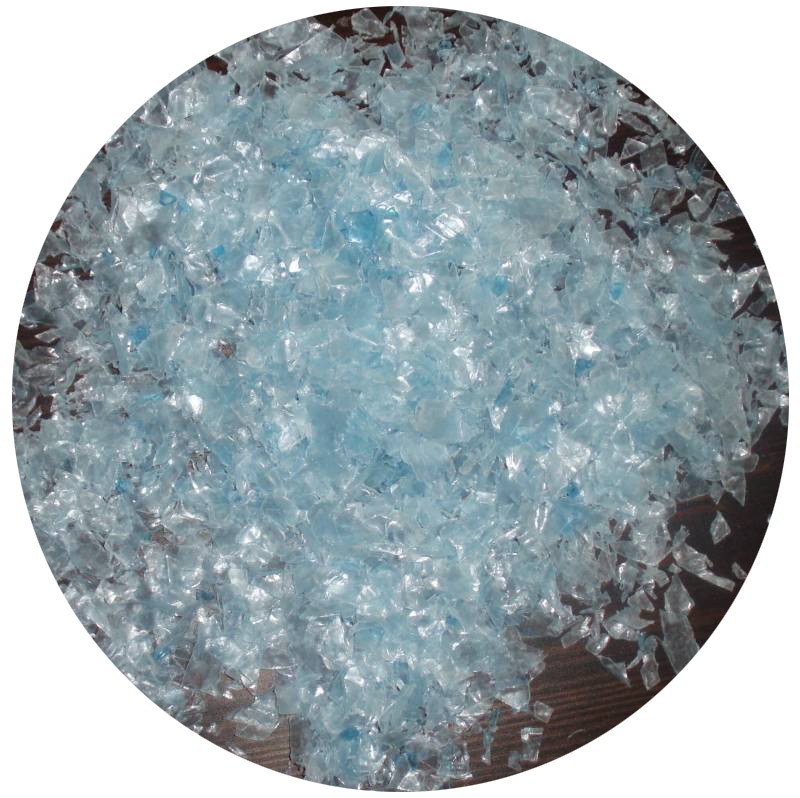

Materiał końcowy Zredukowany do płatków.

Statyczna klinga: Klingi szerzej mogą być ostrzone 20-25 razy, co zaoszczędzi kosztów klina. Materiał: 9Crsi/ SKD-11/D2.

Rotor: Z mocnym wirnikiem i wałem.

Wał wykonany z nierdzewnej stali 45# z przetwórstwem termicznym.

Siatkowanie: Średnica siatki: 14mm,

Grubość siatki: 10mm

Motor: Utrzymuje dobrą wydajność silnika i może być używany przez długi czas.

Używany w linii mycia recyklingu butelek PET

Używany w linii mycia recyklingu butelek HDPE

PEŁNA OBSŁUGA PO SPRZEDAŻY:

Wysyłamy inżynierów, aby pomogli w instalacji, uruchamianiu i szkoleniu.

• Przed ogłoszensprzedażą: oferujemy klientowi szczegółowe propozycje techniczne, podpisujemy umowę sprzedaży itp.

• Podczas sprzedaży: dostarczamy szczegółowego układu, instrukcji montażowych oraz wsparcia technicznego dla klientów.

• Po sprzedży: organizujemy przyjazd inżyniera do zainstalowania maszyny i szkolenia pracowników naszego klienta.

• Mamy 24-godzinną linijkę obsługi klienta do rozwiązywania problemów po sprzedaży.

• Dostarczamy bezpłatne części zapasowe razem z maszyną.

• Ofiarujemy długoterminowe części zapasowe każdemu klientowi.

• Zawsze aktualizujemy nowe technologie dla każdego klienta.

FAQ:

Q: Jaka jest długość okresu gwarancji dla maszyny?

A: Rok bezpłatnie

Q: Z jakiego materiału jest wykonana maszyna?

A: Z nierdzewnej stali i stali węglowej.

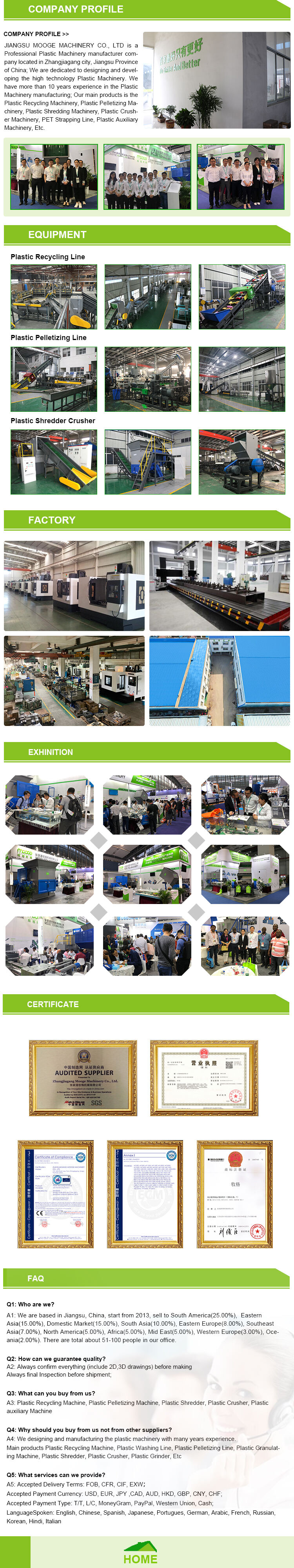

P: Czy jest Pan producentem lub przedsiębiorstwem handlowym?

A: Somy profesjonalnym producentem maszyn plastikowych, zlokalizowanym w mieście ZHANGJIAGANG, w prowincji Jiangsu w Chinach.

Aby lepiej zrozumieć Twoje potrzeby, prosimy o podanie poniższych informacji dotyczących produktu:

1. Jakiego rodzaju materiał zamierzasz przetwarzać?

2. Jaka jest wymagana przez Ciebie pojemność produkcyjna?

3. Czy posiadasz jakiekolwiek inne maszyny do recyklingu?

AR

AR

BG

BG

HR

HR

CS

CS

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

BE

BE

MK

MK

HY

HY

AZ

AZ

KA

KA

HT

HT

BN

BN

HMN

HMN